In the modern foundry industry, permanent casting is gradually becoming one of the important processes to improve product quality and production efficiency. Compared with traditional sand casting, permanent casting uses metal molds, which can achieve more precise shapes, higher strength and better surface quality. It is widely used in automobile manufacturing, aerospace, mechanical parts and other industries.

Process characteristics of permanent casting

Permanent casting refers to a process of pouring metal using metal molds instead of disposable sand molds. It mainly includes the following methods:

Gravity Casting: Using gravity to fill molten metal into metal molds, suitable for materials such as aluminum alloys and copper alloys.

Low Pressure Casting: Injecting liquid metal into the mold through low pressure, suitable for parts requiring high precision and high strength.

Die Casting: Using high pressure to inject molten metal into the mold cavity for rapid prototyping, suitable for mass production.

Advantages of permanent casting

Improve casting quality: Since the metal mold can maintain a stable shape under high temperature environment, the castings of permanent casting have higher dimensional accuracy and reduce the need for subsequent processing.

Enhance material properties: The process can control the cooling rate and make the internal structure of the casting denser, thereby improving mechanical properties such as strength, hardness and wear resistance.

Improve production efficiency: The molds of permanent casting can be reused, which is suitable for mass production and helps to reduce the cost of each piece.

Reduce material waste: Compared with sand casting, the metal molds of permanent casting will not be consumed during the production process, which can greatly reduce the generation of waste and improve resource utilization.

Improve surface quality: Due to the high precision of the metal mold, the surface of the casting is smoother, reducing the need for polishing and processing.

Industry application

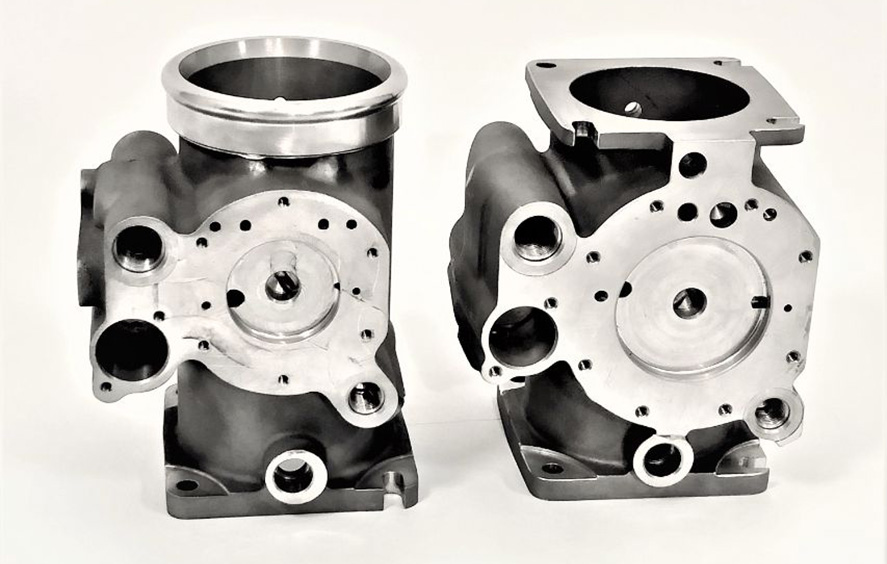

Automotive industry: engine block, gearbox housing, suspension system components, wheel hub, etc.

Aerospace: high-precision structural parts, aircraft engine components, cabin equipment parts.

Mechanical manufacturing: high-strength parts such as pump bodies, valves, gears, bearing seats, etc.

Electronic products: precision parts such as radiators, housings, connectors, etc.

Challenges and solutions of permanent casting

Although permanent casting has many advantages, it still faces some challenges in the actual production process:

High initial mold cost: The manufacturing cost of metal molds is high and suitable for mass production. The solution is to adopt modular mold design to reduce replacement costs.

Thermal fatigue problem of metal molds: After long-term use, the mold may fail due to thermal fatigue. The mold life can be extended by optimizing the cooling system and using high-heat-resistant materials.

Limitations of applicable materials: Permanent casting is suitable for materials with low melting points such as aluminum alloys and copper alloys, while special coatings and high-temperature alloy molds are required for high-melting point steel materials.

Future development trends

With the growing demand for high-precision and high-performance castings, the permanent casting process is constantly upgrading. For example, the combination of vacuum casting and precision cooling technology can further optimize the casting quality. In addition, the development of environmentally friendly metal mold materials will also promote the application of this process in more fields.

Intelligent casting: Introduce automated robots and intelligent control systems to improve production efficiency and consistency.

Environmentally friendly casting materials: Develop low-carbon emission, recyclable mold materials to reduce the impact on the environment.

Composite casting technology: Combine different casting methods, such as pressure casting and gravity casting, to improve the performance of castings.

Conclusion

Permanent casting, as an advanced casting process, is becoming a new trend in the development of the industry with its high quality, high efficiency and environmental protection advantages. In the future, with the continuous innovation of technology and the expansion of applications, permanent casting will play an important role in more manufacturing fields.Contact us to learn more about permanent1

Whats App number:19050516721

Phone: 19050516721/contact.html

E-mail: Judy@haozhifeng.com