Aluminum alloys are widely used in industries such as aerospace, automotive, construction, and aluminum casting due to their lightweight, strength, and corrosion resistance. Among the most popular alloys are 6061-T6 and 6061-T651. While they share similar chemical compositions, their mechanical properties and applications differ significantly. This article explores the key differences between 6061-T6 and 6061-T651 aluminum, helping you choose the right material for your project.

Overview of 6061 Aluminum Alloy

6061 aluminum is a versatile alloy composed primarily of magnesium and silicon. It is known for its excellent weldability, machinability, and resistance to corrosion. This makes it a preferred choice for structural applications, aluminum casting, and manufacturing components in demanding environments.

What is 6061-T6 Aluminum?

6061-T6 aluminum is heat-treated and artificially aged to enhance its strength and hardness. The "T6" temper designation indicates that the alloy has been solution heat-treated and then artificially aged.

Key Properties of 6061-T6:

•Tensile Strength: 45,000 psi (310 MPa)

•Yield Strength: 40,000 psi (276 MPa)

•Elongation: 8-10%

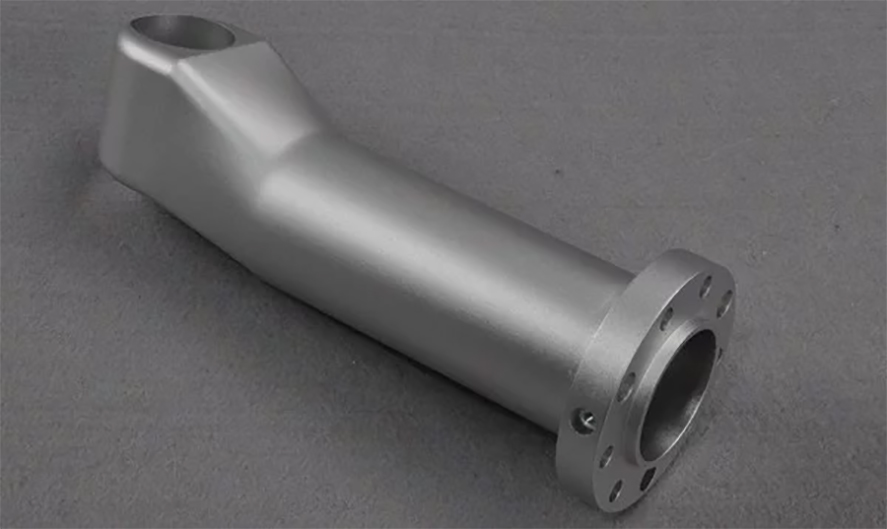

•Applications: Aerospace components, automotive parts, bicycle frames, and aluminum casting.

What is 6061-T651 Aluminum?

6061-T651 aluminum undergoes additional stress-relieving processes compared to 6061-T6. The "T651" temper designation means the alloy has been solution heat-treated, stress-relieved, and artificially aged.

Key Properties of 6061-T651:

•Tensile Strength: 45,000 psi (310 MPa)

•Yield Strength: 40,000 psi (276 MPa)

•Elongation: 8-10%

•Additional Benefits: Improved dimensional stability and reduced internal stresses.

•Applications: Precision machinery, structural components, and high-stress environments.

Key Differences Between 6061-T6 and 6061-T651

While both alloys share similar mechanical properties, their processing and applications differ:

1.Stress-Relieving Process:

o6061-T6: No stress-relieving process.

o6061-T651: Undergoes stress-relieving, making it more stable for precision applications.

2.Dimensional Stability:

•6061-T6: May experience slight warping under high stress.

•6061-T651: Better suited for applications requiring tight tolerances.

3.Cost and Availability:

•6061-T6: More widely available and cost-effective.

•6061-T651: Slightly higher cost due to additional processing.

Applications in Key Industries

Both 6061-T6 and 6061-T651 are used extensively in industries such as:

•Aluminum Casting: Ideal for creating lightweight, durable components.

•Aerospace: Used in aircraft frames and structural parts.

•Automotive: Suitable for engine components and chassis.

•Construction: Commonly used in bridges, towers, and architectural structures.

Choosing the Right Alloy for Your Needs

When deciding between 6061-T6 and 6061-T651, consider the following factors:

•Precision Requirements: For high-precision applications, 6061-T651 is the better choice.

•Budget Constraints: If cost is a concern, 6061-T6 offers excellent value.

•Stress Conditions: For high-stress environments, 6061-T651 provides greater stability.

Conclusion:

Both 6061-T6 and 6061-T651 aluminum alloys offer exceptional strength, corrosion resistance, and versatility. Understanding their differences is crucial for selecting the right material for your specific application. Whether you’re involved in aluminum casting, aerospace, or automotive manufacturing, Qingdao Haozhifeng can provide high-quality aluminum products tailored to your needs.

Call to Action:

Looking for reliable aluminum suppliers? Contact us today to learn more about our 6061-T6 and 6061-T651 aluminum products. Visit our website or call us at +86 18661715326 for a quote.

Whats App number:19050516721

Phone: 18661715326

E-mail: Judy@haozhifeng.com